By Clay Imports

- What is Clay?

- How do you turn clay into stuff?

- Can I make a custom breeze block?

- How can I make a breeze block prototype?

What is Clay?

Clay is a natural type of soil that can be molded thanks to its different plasticity characteristics. Because clay can easily be molded, it is an ideal material for making product prototypes, such as breeze blocks. Fired clay is often referred to as terracotta and is used in other building products such as tiles, bricks, and decorative sheathing.

How do you turn clay into stuff?

Clay is an easy and malleable material to work with that can be used by anyone, no matter your level of expertise. From full time ceramic artists to clay molding for beginners, clay molding techniques are numerous; you just need to experiment and find the best molding technique for you.

The most used technique for shaping clay is simply to use your hands. In order to mold with clay properly, it has to be pounded flat and then it can be bent and shaped with your hands. Basic hand tools such as boxwood, loop and ribbon, ribs and scrapers, needle tools, sponges, shapers, and sgraffito tools can also be incorporated into this process for greater accuracy and more sophisticated clay products. You can also make your own tools with things around your home or workshop, so don't hesitate to get creative!

Hand clay molding is easy for beginners and experts alike

One of the most famous clay molding techniques is spinning. As the name implies, spinning clay consists of shaping clay as it is being rotated in a spinning table. This technique uses the force of the rotation to lessen manual work and is widely used in ceramics fabrication. Spinning clay on a potter’s wheel creates primarily circular items, such as vases or pots.

Clay spinning is one of the most known molding techniques

For more angular clay items, clay artists choose a technique known as mold compression. This clay molding technique consists of packing clay into a mold and then applying pressure to the clay so that it takes the shape of the mold. Unlike spinning or hand shaping, this technique requires the previous development of a mold, but in exchange, you can end up with a very elaborated clay sculpture.

You can make any shape using clay molds

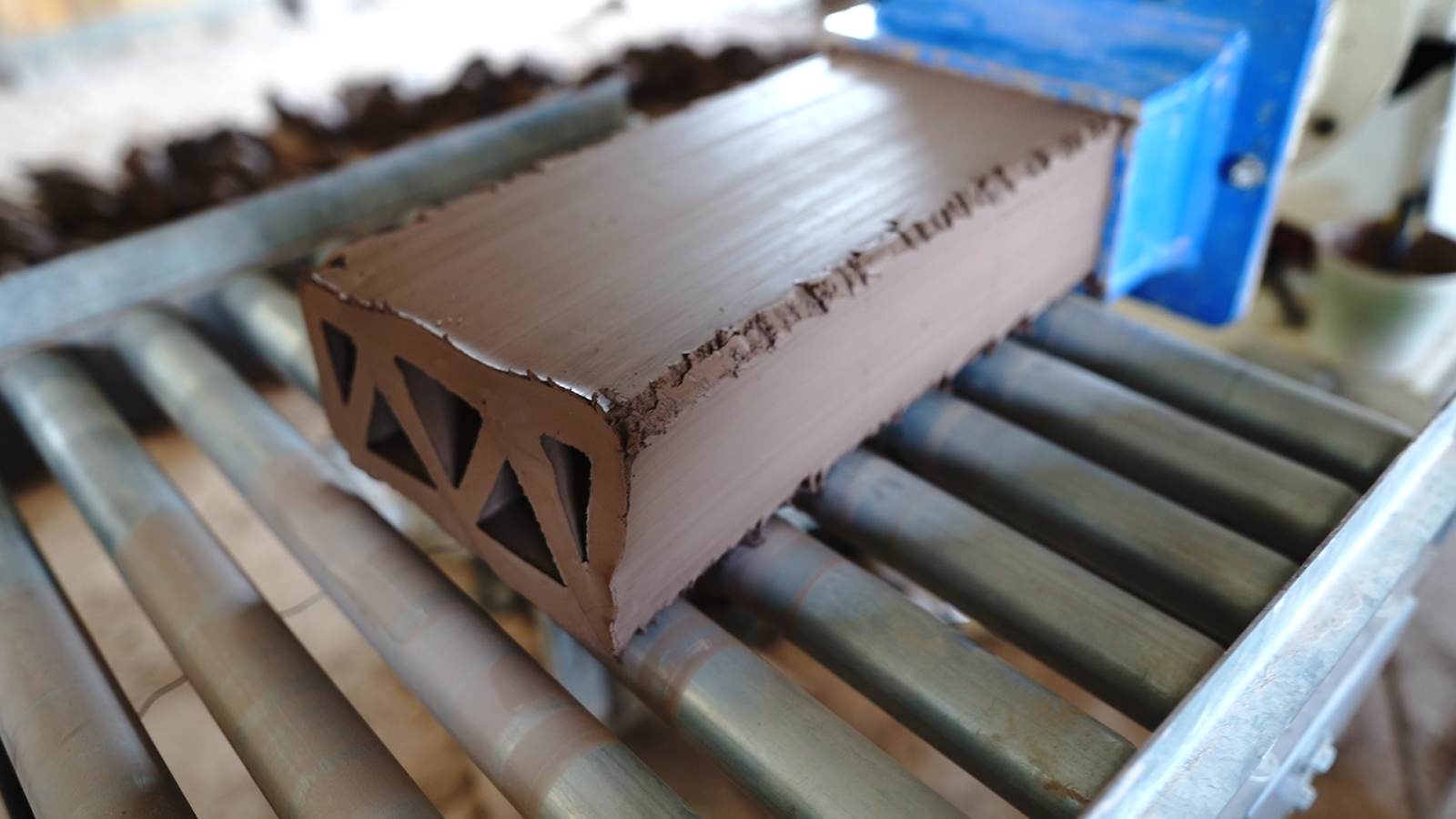

Lastly, clay can be extruded through a patterned die. This process is similar to how play-doh is squeezed into fun shapes. Because it is fast and requires minimal manual labor, extruding clay is ideal for repetitive pattern production such as making breeze blocks. Extrusion dies are costly though and it can take up to a full day to remove and install a new die on an extrusion machine.

Clay block coming out from a extrusion machine

Can I make a custom breeze block?

Extruding clay to make breeze blocks is efficient, but due to the high investment of making new dies, developing custom breeze blocks can be expensive. So, if your goal is to put a new breeze block pattern into production, you are going to need to start by making clay prototypes without extrusion. This can guarantee the best results for your clay breeze blocks.

Extruding clay to make breeze blocks is efficient, but due to the high investment of making new dies, developing custom breeze blocks can be expensive. So, if your goal is to put a new breeze block pattern into production, you are going to need to start by making clay prototypes without extrusion. This can guarantee the best results for your clay breeze blocks.

How can I make a breeze block prototype?

The best way to build your first tile or breeze block prototype is by shaping your designs by hand. You can shape clay to the pattern of your designed breeze block, doing any correction or new arrangement on the go. This will require time, patience and some practice but it can also result in an affordable, breeze block prototype.

Clay Imports is also starting to make clay breeze blocks prototypes with 3D printing. 3D printed pieces will most likely be made of plastic, which can increase the budget for your project.

Regardless of your choice in creating your clay prototype, once you have your prototype, allow the piece to dry in a shaded area for several days then transfer it to direct sunlight until it is dry. For finishing touches, lightly sand the surface. Keep in mind that this handmade style breeze block will exhibit natural variations, which are inherent traits of natural materials like Terracotta. These variations in color, texture and sheen are not defects but rather a natural part of the product. If you decide to buy any of our clay and terracotta products, we highly recommend ordering samples before making a final purchase to confirm and appreciate these natural variations in each tile and block.

We also recommend taking a look at our Clay Care products. These maintenance items have been carefully tested with our products, and they are designed to preserve your tiles' beauty, ensuring their longevity and durability. From sealers to cleaners, purchasing these maintenance items together with your tiles not only simplifies your order but also prepares you to enjoy your tiles for a long time.

Nick showing how clay can transform into a beautiful breeze block

Now you have a clay breeze block prototype! Think your prototype turned out cool? Reach out to us if you’d like to talk about production options! Contact us at contact@clayimports.com

Share

Share

Pin it

Pin it